Mon- Fri / 08:00 - 18:00

|

+32 (0)87 339 381We manufacture simple or complex mechanical components and assemblies in all types of metals and polymers for SMEs, large companies and multinationals in Belgium and abroad.

Our customers come from various sectors (medical, energy, industry, defence, food…), which provides substantial experience in manufacturing varied and complex parts.

Today, we have the possibility to manufacture all parts in small and medium series according to your plans, models, 3D files. We manage and finalise your projects from A to Z within a short timeframe.

Our research and development team and design office can also provide with machining expertise and an external eye to improve the performance of your part and reduce manufacturing costs. In order to ensure their quality and performance, we also test the parts and can assemble them if necessary.

To carry out our activities, we have high-performance digital machines at the cutting edge of technology run by highly qualified members of staff. We offer our clients quality work in a relationship based on trust.

We manufacture and assemble high quality precision parts in our workshop located in the industrial zone of Les Plenesses (Dison). To do this, we have specific equipment and highly experienced staff. Together, they make us your ideal partner with know-how that has been recognized for more than 50 years.

Our machines allows us to perform CNC turning as well as CNC milling of up to 5 simultaneous axis machining. We have the ability to machine extremely complex parts using our MasterCAM software and our “Aube Expert” module. We are fully equipped to machine magnesium, a particularly interesting material when weight savings are required without having to compromise on mechanical strength.

If necessary, our professional team can also take care of the assembly of the manufactured parts.

Through various partnerships, we also handle a wide range of treatments, whether they are heat treatments or surface treatments.

For all products, we can provide on request: material certificates, dimensional control or others.

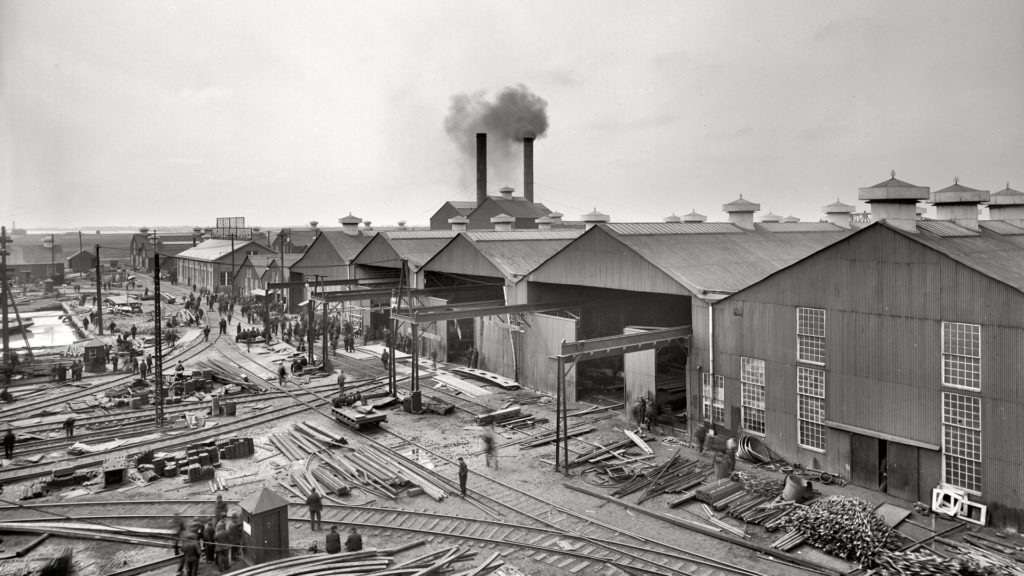

Before becoming LG Precision, we first started in a small workshop in 1968 near Liège, in Verviers. This city was at the time the world capital of wool industry and was full of textile factories. In this favourable economic context, Alfred Lagamme set up his own company specializing in industrial assistance and maintenance services. The “Ateliers Lagamme”were born and they quickly started working for the Walloon weaving industry.

When the textile industry started to decline, a consequent drop in activity is avoided by the rise in the bottling of mineral water and beer, another Belgian specialty. This has allowed the workshop to redirect its activity towards bottling. The support of the racing car industry will further enhance the development of the machine shop. This opportunity will come from the proximity of the Spa Francorchamps racetrack.

Over time, the “Ateliers Lagamme”have added mechanical parts machining to their service catalogue in order to meet an ever-increasing demand.

Today, the “Ateliers Lagamme”have become LG Precision. We provide our expertise throughout the world. The skills we acquired over time in the field of mechanics allow us to develop real partnerships with our customers; they consider us as a detached R&D or technical assistance unit.

The benefit is to avoid permanent costs for one-off services allowing both parties to maintain a neutral approach to problems and a rapid response to solutions..